Welcome To The 3d Printing Sector

Work has actually been done to simplify the CAD/CAM procedure of making functionally rated scaffolds by utilizing a library of polyhedrals to regulate the porosity. The porosity then processed is connected to the stiffness of the scaffold and demonstrated with PCL in SLS. A complete evaluation on the advancement of the design of microarchitecture can be located. In addition, FEA has been utilized to aid layout microarchitecture as well as anticipate mechanical buildings for SLS.

Simply affix a tiny item of sponge with a binder clip to the filament before it enters the extruder. Add a decrease of olive oil to the sponge to lubricate the hotend and prevent stringing. Your brand-new printer might have come with 2 nozzles, one installed on the hotend and an extra. The majority of FDM 3D printers rely upon brass nozzles that wear from use, especially if you’re running filament with rough glitter or Wraps fibers. The downside to plethoras is they create a rough base on your print while wasting a little time as well as material. Believe me, they’re still worth it for new people just getting going.

Polycarbonate. According to numerous makers and reviewers, polycarbonate (PC) is considered the best consumer filament out there. Computer can yield very high-strength parts when published correctly with an all-metal warm end as well as an unit.

In the indirect technique, mold and mildews are printed utilizing commercially readily available plaster powder, as well as eco-friendly polymers are cast right into the published mold and mildew. Various materials can be cast under the comparable printing process criteria, whereas private procedure parameters need to be maximized to make best use of the develop resolution in a traditional straight 3DP approach. This innovation can be applied to treat individuals with zygomatic bone fractures.

What Is Additive Manufacturing?

click this over here now procedure eliminates surface irregularities, gets rid of recurring powders, and also develops a consistent matte finish. To execute the annealing procedure, the 3D published part is put in a stove, a temperature-controlled chamber, or a heated water bath, relying on the material as well as the preferred end result. The temperature as well as duration of the annealing procedure are carefully regulated to accomplish the desired enhancements without endangering the part’s measurements, Wraps surface area finish, or overall quality.

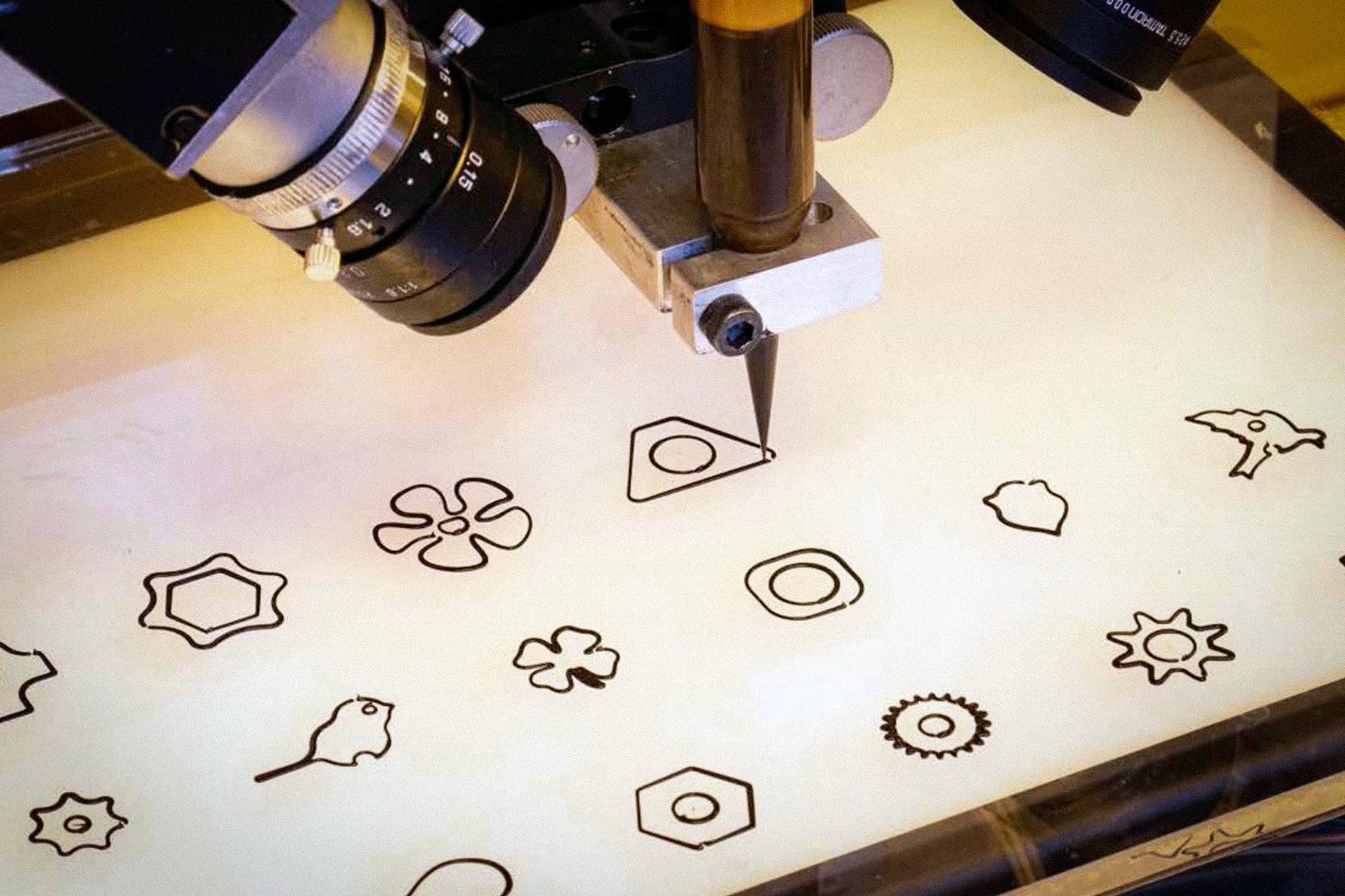

Each material’s detailed datasheet is also linked under each offering. In order for a 3D printer to construct a component, the CAD data has to be exported into a STL file. A STL data is composed of triangulars developing the surface of the component, creating faceting of the 3D version.

Change The Nozzle With A Fresh One

As a result, stamina and also rate make triangular infills the very best choice amongst many 3D fanatics. These tips are a good place to begin, however there is much to learn as you work your means as much as the title of 3D printing professional. Unlike aluminum or various other materials, glass has less of a propensity to flaw under pressure. Printing on a perfect flat surface like glass ensures the bed remains degree after each print work. When printing, all the slicer values are established, and also extrusion is computed with the nozzle size in mind.

Nonetheless, this fabrication method is typically restricted to hydrogel materials such as alginate and also fibrin, which might not be suitable for the implantation in biological environments that require strong mechanical homes. Instance applications are rat smooth muscle mass cell-laden collagen beads (650 μm diameter) to produce details cell spatial patterns in 3D. This SFF approach is specifically great for low viscosity materials and the buoyancy as a result of the thickness matching of the extruded material to the liquid tool avoids collapse of the shape. The strand thickness can be differed by product viscosity, deposition rate, extrusion suggestion diameter, as well as used pressure. Stereolithography is a 3D printing modern technology that uses ultraviolet light to uniquely cure fluid photopolymer resins layer by layer. SLA published parts usually have a greater resolution and smoother surface coating compared to FDM printed parts.

Or else they will attempt to print on air, even if it just one layer. If your head is clogged up with material outside … it’s probably since your product had no where else to go. This is my first-person account of how I have gone through the mine-field of 3D printing and ran away relatively untouched. I was out in the field on a project and I had this actually great equipment in your home. I had read everything I might during the previous year about 3D printing. Much of my artwork is 3D based, and I’ve been dealing with 3D programs for two decades.

Or else they will attempt to print on air, even if it just one layer. If your head is clogged up with material outside … it’s probably since your product had no where else to go. This is my first-person account of how I have gone through the mine-field of 3D printing and ran away relatively untouched. I was out in the field on a project and I had this actually great equipment in your home. I had read everything I might during the previous year about 3D printing. Much of my artwork is 3D based, and I’ve been dealing with 3D programs for two decades.